Hydraulic Pump, Motor, Valve Service & Repair

Today’s complex hydraulic systems incorporate specialized controls for pumps, motors and valves.

Proper setup requires knowledgeable individuals with capable test equipment. Whether it’s a constant volume vane pump, a gear pump or a variable volume, pressure compensated horsepower limiting pump, we can fulfill all your requirements.

Our Goal is to provide you the highest quality repair, quick and accurate turnaround times, and competitive pricing.

Pumps & Motors:

- Open and closed loop

- Fixed and variable displacement

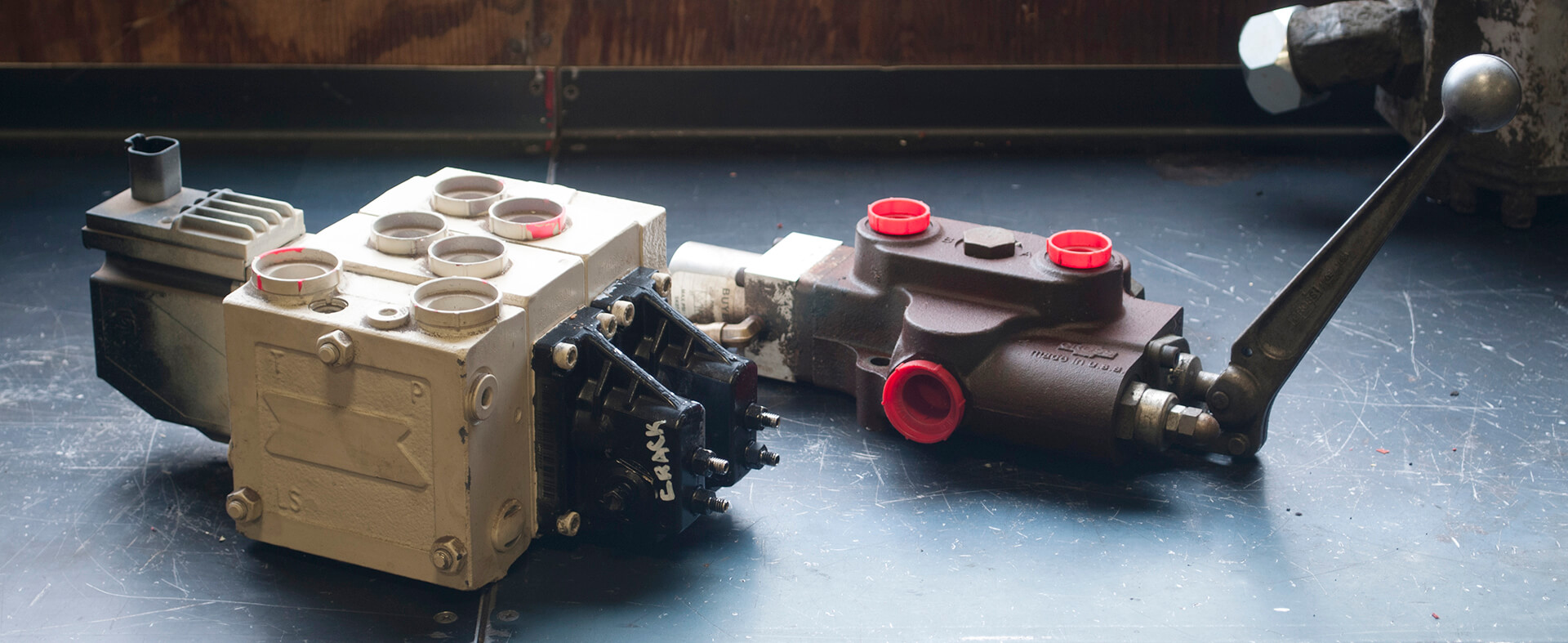

Valves:

- Pressure and directional control

- Proportional and servo

Rotary Actuators:

- Vane and rack & pinion

Gear Boxes:

- Planetary and worm gear

- Mobile and industrial

- Helical, bevel and winches

Hydraulic Gear Pump

When repair indicators are present, rebuilding a gear pump is an economical option which fully restores the hydraulic system to optimum performance.

Repair Includes:

- Reseal, Repair, Replace

Repair Indicators:

- Oil Leak

- Pump not producing required output

- Motor not producing required output torque/speed

- SOS report indicates high levels of metallic particles in oil

- Excessive noise, heat or vibration

- Scheduled Custom Hydraulic Service Inspection

Lapping Machine:

We offer lapping capabilities to rectify and refurbish thrust and valve plates for pumps and motors. This allows us to improve turnaround time and reduce the overall cost of repairs.

Schroder Hydraulic Test Bench:

- Allows all rebuilt pumps, motors, cylinders, and valves to be tested to factory specifications before installing them in a working system.

- Allows rebuilt power shift transmissions to be hydraulically tested assuring positive clutch pack sealing.

- Allows testing of hydrostatic transmission rebuilds.